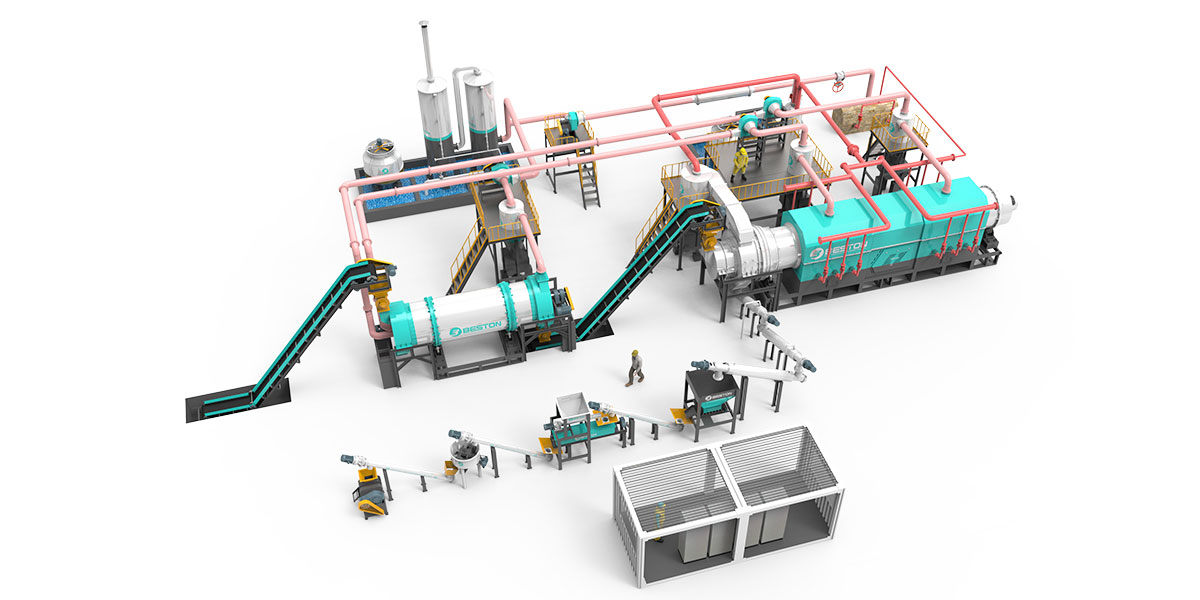

Advanced Charcoal Making Machine – Various Capacities To Suit the Customer’s Needs

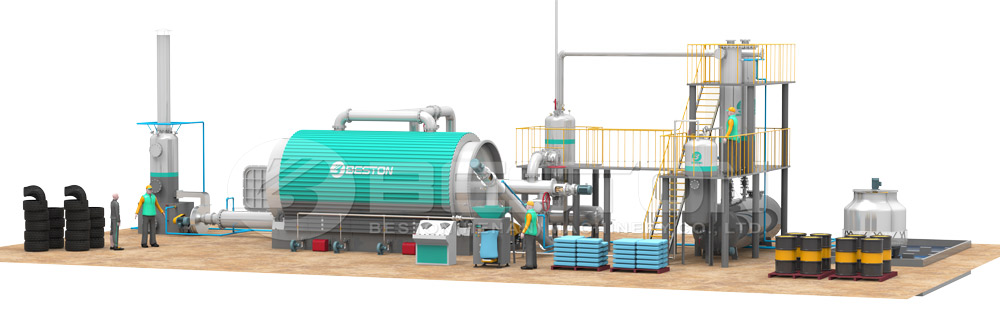

Charcoal has wide applications all over the world. The old way of making charcoal is not environmentally friendly, and that process is being phased out. Nowadays, a technologically advanced charcoal making machine is more eco-friendly and more efficient in charcoal production. The operation is also more automatic, thus saving human labor. The charcoal making machine can use all types of raw materials including coconut and palm shells, wood, sawdust, bamboo, rice husks, and more.

The machines come in various capacities to suit the customer’s needs. Capacity ranges from 300 kg to 5,000 kg per hour. The manufacturer can help you choose the machine that can meet your capacity requirements.

Many customers do not realize the many benefits of a charcoal making machine. Not only would you get charcoal from processing the raw materials, but you also get other products that are useful such as wood vinegar, tar, and combustible gas.

The main product that is produced is charcoal from biomass with biochar production equipment for sale. Charcoal serves as fuel for many applications. It is used in metal smelting because of it does not consume as much energy. Charcoal is also used in agricultural applications. It can be added to soil to modify the soil’s pH and to loosen the soil for a more fertile planting environment. Charcoal can also be processed into activated carbon, which is more valuable.

Wood vinegar is the other product produced by the charcoal making machine. It is a fungicide with sterilization properties and is often used in the medical industry, food industry, forestry, and agriculture. Wood vinegar supports the growth of plants, and it can extend the shelf life of certain food items. There are many health-related applications that use wood vinegar, and this is a popular product.

During the carbonization process, combustible gas is produced as heating fuel. This is used in the wood charcoal making machine itself, making the plant practically self-sufficient. Using combustible gas saves on energy costs.

The charcoal making machine is eco-friendly and can be set to run automatically. It has a energy-saving design that recycles combustible gas as fuel. It uses the heat that is generated inside the reactor to dry and carbonize the raw material simultaneously. The machine can operate automatically without requiring additional fuel, thus saving energy and labor.

The charcoal making machine can produce charcoal from raw materials at a rate of 3:1. With an hourly capacity of 300 kg to 5000 kg, you can easily produce tons of charcoal every day.

The rice husk charcoal making machine is constructed with high-quality steel and will provide your business with many years of service. The dealer stands by its products and will provide comprehensive service support over the lifespan of the machine. With eco-friendly design and the production of many useful by-products, the machine is a good investment.