Pyrolysis Technology: Transforming Waste Management and Fueling a Greener Future

As the world grapples with the twin crises of environmental degradation and resource depletion, innovative waste management technologies like pyrolysis are stepping into the spotlight. By converting waste materials into valuable energy products, pyrolysis is emerging as a cornerstone of sustainable industrial development. This article explores the broader impact of pyrolysis technology, from green innovation to industry transformation and economic implications.

Revolutionizing Waste Conversion

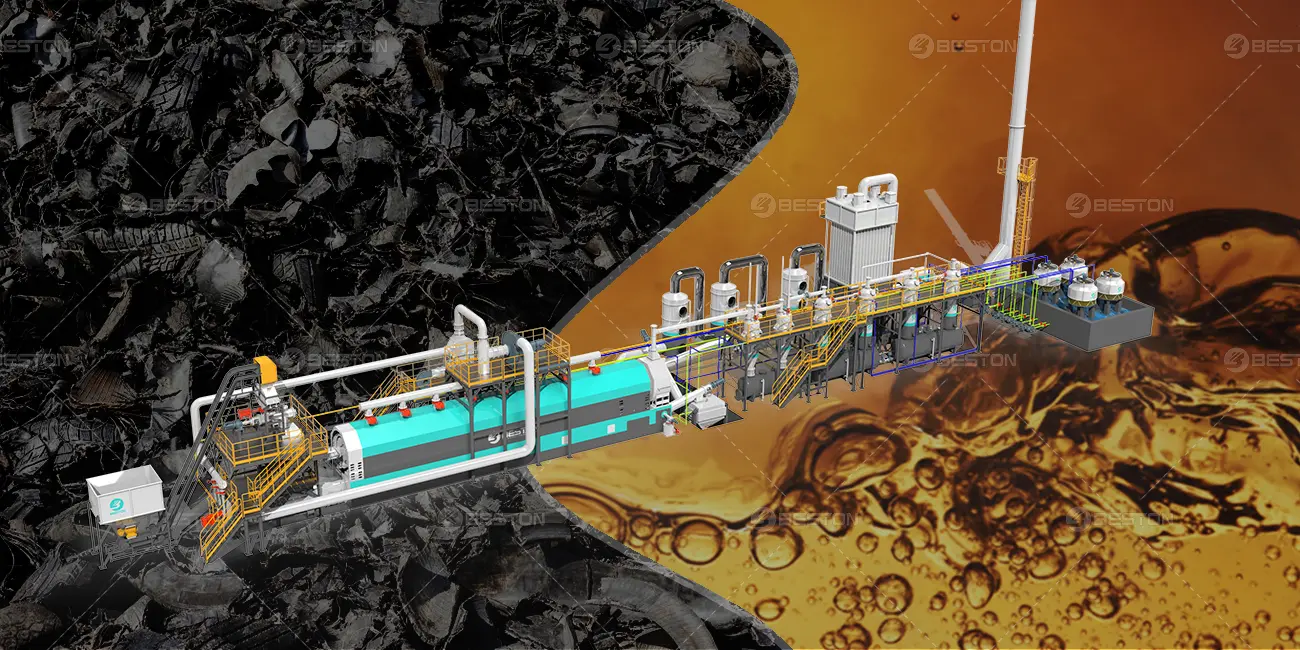

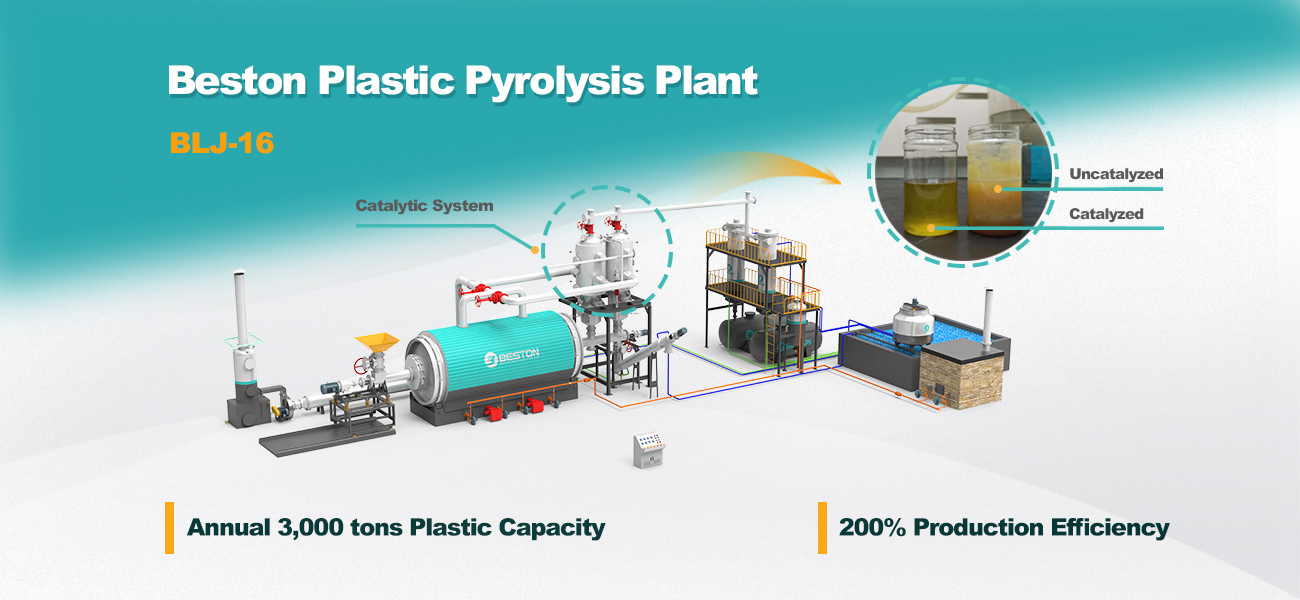

Pyrolysis is a thermochemical decomposition process that converts organic materials such as plastic, rubber, and biomass into liquid fuel, syngas, and carbon black under an oxygen-free environment. Unlike traditional incineration, pyrolysis offers a cleaner, more efficient alternative that mitigates harmful emissions and recycles end-of-life materials. This technology not only addresses waste accumulation but also creates a circular economy by repurposing discarded materials into commercially viable products.

Economic Implications and Investment Opportunities

Pyrolysis is not just an environmental solution—it’s a financial one too. The pyrolysis plant cost varies depending on system size, automation level, and output yield, but the return on investment is increasingly attractive. The produced pyrolysis oil can be used as industrial fuel or refined further, while byproducts like carbon black and steel wire add economic value.

Moreover, governments worldwide are offering subsidies, tax incentives, and carbon credits to businesses that invest in green technologies. This encourages more enterprises to evaluate pyrolysis as a long-term cost-saving mechanism and a profitable investment. Startups and entrepreneurs are also entering the market by acquiring small pyrolysis machine to launch localized recycling ventures or energy recovery units, which adds another layer of grassroots-level industrial impact.

Industrial Applications and Global Expansion

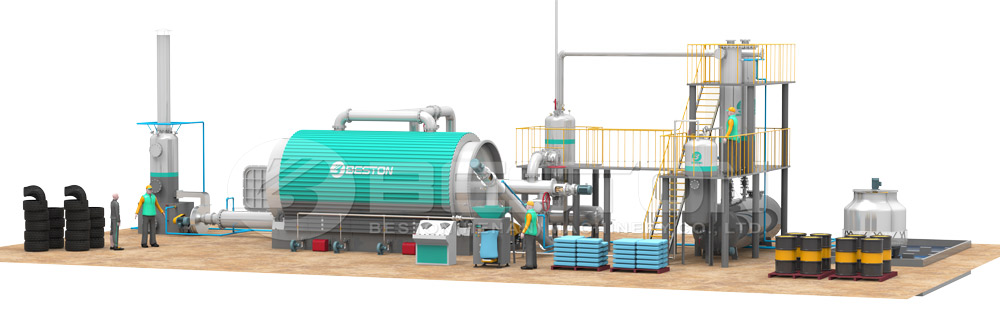

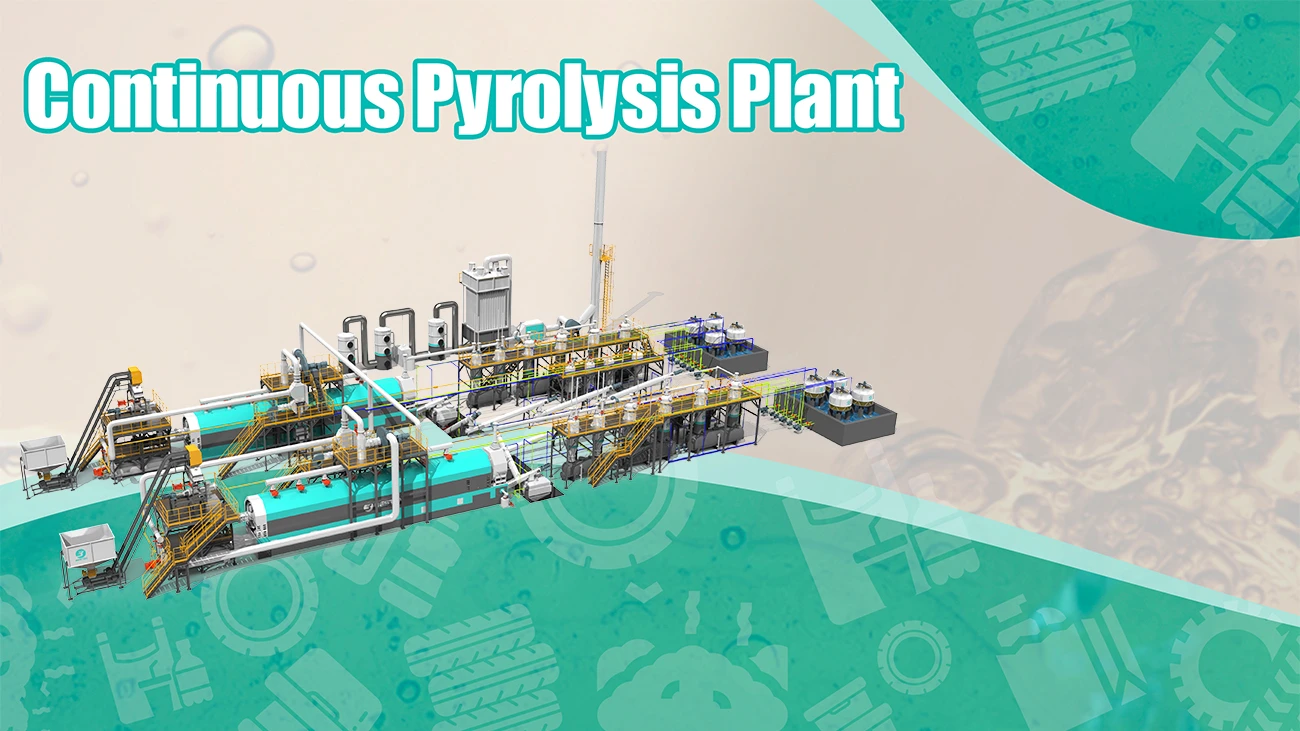

Industries around the world are increasingly adopting pyrolysis systems to align with sustainability goals. From waste management firms to oil refiners and municipal governments, organizations see pyrolysis as a scalable solution to rising waste and energy demands. Whether installing a small pyrolysis machine for pilot testing or investing in a fully operational continuous pyrolysis plant, businesses are adapting to this technology in response to both regulatory pressure and environmental responsibility.

Leading companies like Beston Group have become global facilitators of this transition. They provide modular, automated pyrolysis systems tailored to different feedstocks and capacities, enabling clients across sectors to adopt this eco-friendly innovation efficiently. This adaptability ensures that even developing regions can implement pyrolysis solutions without significant infrastructural investments.

Impact on the Circular Economy and Sustainable Development

The role of pyrolysis in promoting a circular economy cannot be overstated. By closing the loop on resource consumption, it allows materials like plastic and rubber to re-enter the production cycle in the form of fuels and raw materials. This reduces the dependence on virgin fossil fuels, decreases greenhouse gas emissions, and supports climate resilience efforts.

Further, the scalability of continuous pyrolysis plant makes them ideal for regions aiming to improve their waste management infrastructure and meet their Sustainable Development Goals (SDGs). It also supports cleaner urban environments by reducing landfill dependency and mitigating air and soil pollution.

Future Outlook and Global Collaboration

As awareness of environmental stewardship grows, so too does the global collaboration around advanced waste conversion technologies. Countries are beginning to share research, technology standards, and investment frameworks to foster the global adoption of pyrolysis. This includes partnerships between private companies, government agencies, and environmental organizations.

Companies like Beston Group are instrumental in this evolution. By offering turnkey solutions, technical training, and post-installation support, they are empowering communities and businesses to join the green transition. Their emphasis on innovation and adaptability has helped pyrolysis gain traction in both urban and rural settings.

Conclusion

Pyrolysis technology represents a paradigm shift in how the world handles waste and energy. It is an innovation that not only solves pressing environmental challenges but also paves the way for economic growth and industrial diversification. From lowering pyrolysis plant cost to enhancing system efficiency, ongoing research and innovation continue to make this technology more accessible and impactful.

In the journey toward a greener, more sustainable world, pyrolysis is more than a tool—it’s a transformative force that empowers industries, supports communities, and protects the planet for future generations.