Regulations on Pyrolysis Plants: What You Need to Know

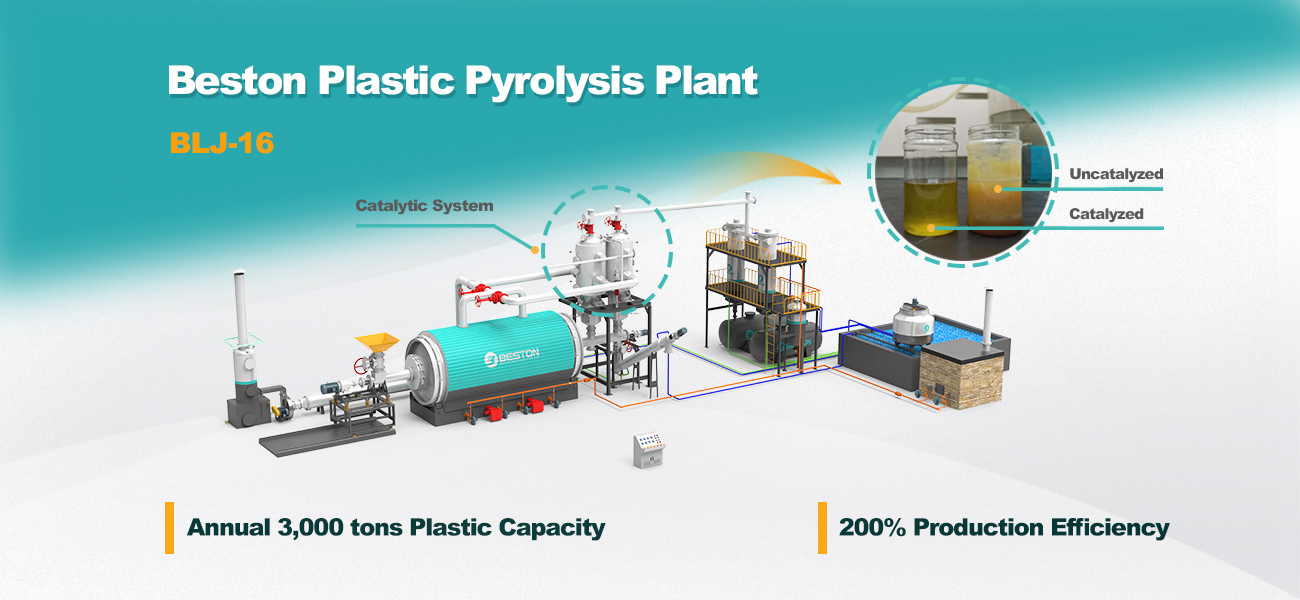

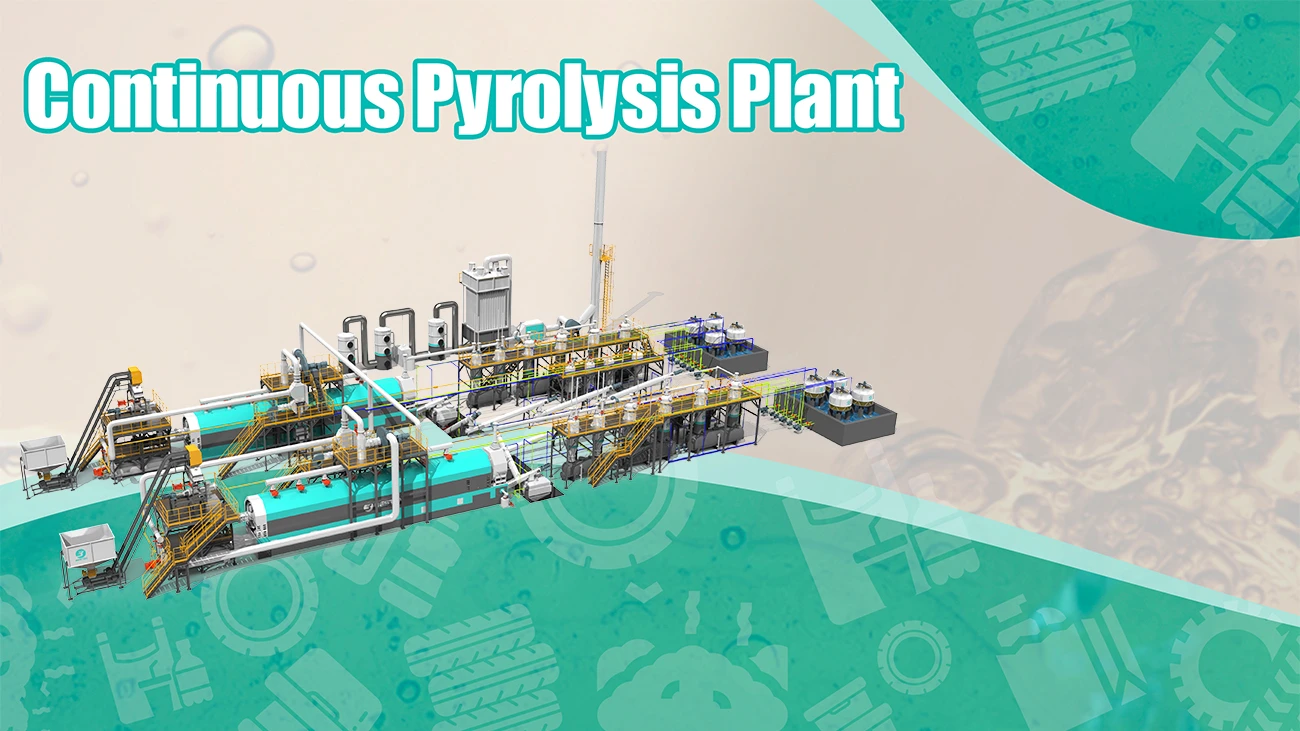

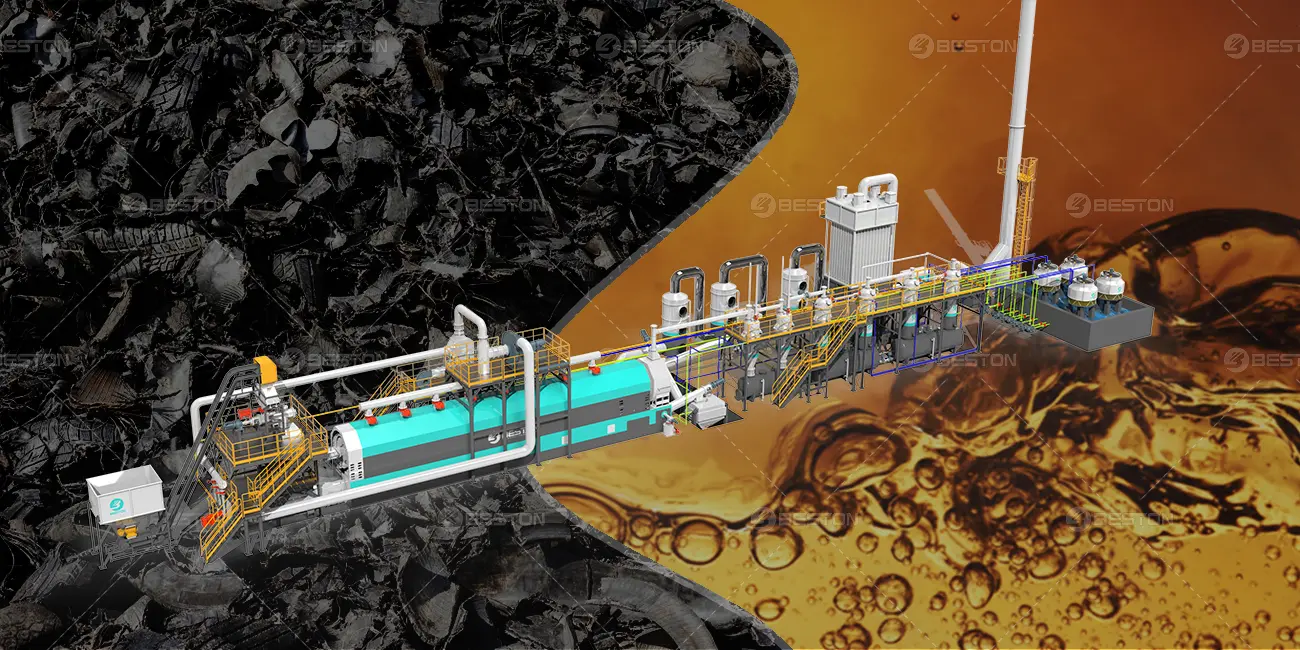

As pyrolysis technology gains popularity as a sustainable solution for waste management and energy recovery, there is a growing need for clear and comprehensive regulations to ensure its safe, efficient, and environmentally responsible operation. Pyrolysis plants, which convert waste materials like plastics, biomass, and tires into valuable products such as bio-oil, syngas, and biochar, must adhere to a range of legal requirements to meet safety standards, minimize environmental impacts, and promote public health. In this blog post, we will explore the regulations that govern pyrolysis plants, what businesses need to know about them, and how to navigate the complex legal landscape.

Why Are Regulations on Pyrolysis Plants Important?

The pyrolysis process involves the heating of organic materials in an oxygen-free environment to break them down into useful by-products. While the technology holds great promise for turning waste into valuable resources, it also involves potential environmental and health risks if not properly managed. Pyrolysis plants can emit gases, release particulates, and produce solid residues that require careful handling. Therefore, stringent regulations are essential to mitigate these risks and ensure that pyrolysis is both a sustainable and safe method for waste disposal.

Key Areas of Regulation for Pyrolysis Plants

Regulations surrounding pyrolysis plants vary by region and country, but most of them address several common areas of concern, including emissions control, waste handling, environmental protection, health and safety, and operational standards.

1. Air Emissions and Air Quality Standards

One of the primary environmental concerns with pyrolysis is air pollution. Although pyrolysis typically produces fewer harmful emissions compared to incineration, the process can still release gases such as carbon monoxide (CO), nitrogen oxides (NOx), volatile organic compounds (VOCs), and particulate matter. As such, regulations often require pyrolysis plants to have advanced air pollution control systems to minimize emissions.

In many regions, pyrolysis plants must meet strict air quality standards established by governmental bodies such as the U.S. Environmental Protection Agency (EPA), the European Union’s Industrial Emissions Directive (IED), or local environmental agencies. These standards specify allowable concentrations of various pollutants in the emissions and may require the installation of technologies like flue gas treatment systems, scrubbers, and electrostatic precipitators to capture and neutralize harmful emissions before they are released into the atmosphere.

2. Waste Handling and Feedstock Requirements

Pyrolysis plants typically handle various types of waste, such as plastics, tires, biomass, and municipal solid waste. Regulations often specify which types of feedstock can be used and under what conditions. For example, certain hazardous materials (e.g., medical waste, radioactive substances, or materials with high chlorine content) may be prohibited due to the potential risks they pose to the pyrolysis process and the environment.

In many jurisdictions, waste tracking and documentation are required to ensure that only authorized waste materials are processed. This helps prevent illegal dumping and ensures that waste is sourced from legitimate and regulated channels. Additionally, waste storage regulations may require specific facilities for storing incoming materials, especially when dealing with hazardous or flammable substances.

Most regulatory frameworks require pyrolysis plants to monitor emissions continuously or at regular intervals and report the results to relevant authorities. These regulations help ensure that plants are complying with air quality standards and allow regulators to take corrective action if emissions exceed acceptable limits.

In many countries, pyrolysis operators must install emissions monitoring systems to measure key pollutants such as CO, NOx, VOCs, and particulate matter. The data collected must be submitted to regulatory bodies, and plants may be subject to periodic inspections or audits to verify compliance. Failure to meet emissions limits can result in fines, shutdowns, or other penalties.

4. Waste Residue Management

Pyrolysis plants generate solid residues, including biochar and ash, which must be properly managed to prevent contamination of land and water resources. Regulations governing the handling, storage, and disposal of these residues typically require plants to test for hazardous substances and ensure that any by-products are either safely disposed of or repurposed for commercial use.

For example, biochar, which is produced from organic materials like biomass or agricultural waste, can have beneficial applications as a soil amendment. However, regulations may require testing to ensure that the biochar is free from contaminants before it is sold or used in agriculture.

5. Health and Safety Standards

Operating a biomass/tyre/plastic pyrolysis plant involves inherent risks, including fire hazards, chemical exposure, and the potential for mechanical accidents. To ensure the health and safety of workers and surrounding communities, pyrolysis plants must adhere to rigorous health and safety regulations. These regulations often cover the following:

- Fire Prevention: Pyrolysis involves high temperatures, so fire prevention and suppression systems are critical. Regulations typically require fire-resistant materials, safety equipment, and emergency evacuation plans.

- Personal Protective Equipment (PPE): Workers at pyrolysis plants must be provided with appropriate PPE, such as gloves, respirators, and protective clothing, to reduce the risk of exposure to hazardous chemicals.

- Training and Certification: Operators must be trained on the safe handling of materials, operation of pyrolysis equipment, and emergency response procedures. Many regions require certifications for workers involved in the operation of hazardous facilities.

6. Permitting and Licensing

Before a pyrolysis plant can be built or operated, companies must obtain the necessary permits and licenses from local, regional, or national authorities. This process typically involves an environmental impact assessment (EIA) to evaluate the potential environmental and social effects of the plant’s operation.

In some cases, pyrolysis operators must also demonstrate that they meet specific sustainability criteria or fulfill commitments to resource recovery and waste minimization. Regulatory bodies may require operators to submit detailed plans outlining how the plant will manage emissions, waste residues, and energy recovery.

7. Compliance with International Standards

In addition to national regulations, some pyrolysis plants may need to comply with international standards. These may include guidelines set by organizations such as the United Nations Environment Programme (UNEP), the World Health Organization (WHO), or the International Organization for Standardization (ISO). International regulations are particularly important for companies operating in multiple countries or those involved in cross-border waste management.

Navigating the Regulatory Landscape

For businesses looking to set up or operate a biomass/plastic/tyre pyrolysis plant, it’s crucial to be well-versed in the relevant regulations and standards. Here are a few tips to ensure compliance:

- Understand Local Regulations: Regulations vary significantly by region, so it’s essential to familiarize yourself with the specific requirements in the jurisdiction where your plant is located. This may involve consulting with legal experts, environmental consultants, or local regulatory bodies.

- Stay Updated on Changing Laws: Environmental regulations are subject to change, so it’s important to stay informed about any updates that could impact your operations. This includes changes in emissions standards, waste disposal guidelines, and safety protocols.

- Invest in Compliance Systems: Implement monitoring and reporting systems that ensure your plant remains in compliance with emissions, waste management, and safety regulations. Automation and real-time data collection can help you stay ahead of regulatory requirements.

- Engage with Stakeholders: Engaging with local communities, environmental groups, and government agencies can help build positive relationships and ensure your plant operates with public trust. Transparency about your operations and adherence to environmental standards can also reduce opposition.

Conclusion: The Future of Pyrolysis Plant Regulation

As pyrolysis technology continues to evolve and gain widespread adoption, the regulatory landscape surrounding pyrolysis plants will likely become more sophisticated and comprehensive. Clear, consistent regulations are essential to ensure that pyrolysis remains a safe, effective, and sustainable solution for waste management. By understanding the regulations that govern pyrolysis plants, businesses can not only ensure compliance but also contribute to a greener, more sustainable future.