Benefits Of Waste Tire Pyrolysis Technology

Waste tires are one of the biggest global contributors to pollution. People incinerate scrap tires because they have a high heat index, but burning rubber results in lots of atmospheric pollutants. Populations are also sending increasing numbers of used tires to landfill sites, where they take over fifty years to decompose. Lack of modern tire recycling technology in the past meant that people had little choice but to dispose of tires in un-environmentally friendly manners.

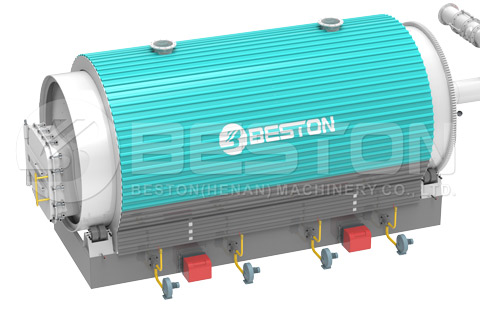

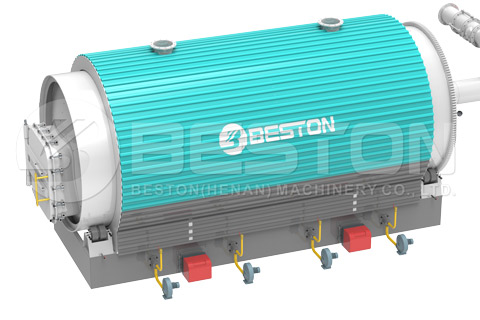

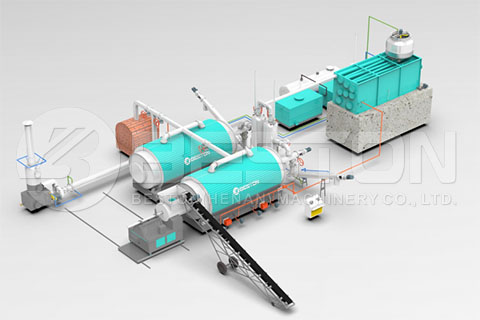

Nowadays, more businesses invest in the latest pollution-free tire recycling machine, namely waste tire pyrolysis plant. Such machines using pyrolysis technology not only help to compact environmental pollution, but they can also improve economical stability for many developing nations. This is because the end products from pyrolysis reactors are sought-after, valuable commodities. It is thought that eco-friendly tire pyrolysis plants are also contributing to better employment opportunities in many countries.

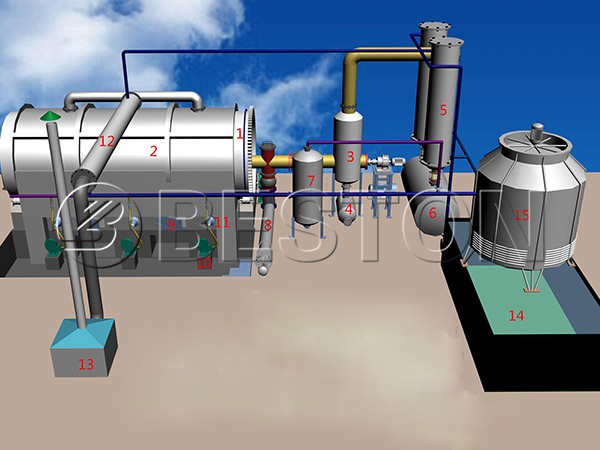

Many people wonder how the pyrolysis process works and how it’s possible to convert waste tires to fuel oil and carbon black without producing any pollution. The secret is the oxygen-free heating chamber. When materials are heated to extremely high temperatures in an oxygen-free atmosphere, instead of burning and producing smoke, they vaporize. The vapor produced can then be distilled and liquified using a sophisticated condensing system. In the case of tyre recycling machine, the condensing system is basically just water-cooled pipework. The vapor that can’t be liquified is combustible gas, which is used to fuel to pyrolysis reactor furnace.

The energy efficiency of modern pyrolysis plants is second to none due to the fact that byproducts from the process can be recycled through the system to heat the reactor. What’s more, the furnace in pyrolysis plant can be fueled using a variety of renewable energy sources. Of course, there are some waste management facilities that are using fossil fuels to power their reactors, but those facilities are unable to take advantage of government grants targeted to businesses committed to reducing their carbon footprints by embracing green technology.

The truth is that the more waste management facilities around the world that embrace the latest tire pyrolysis plant technology, the better for the Earth’s natural environment and the better for economically developing nations. It is hard to think of any disadvantages of waste tire pyrolysis machines. That’s said, initial investment costs can be prohibitive to many businesses. Furthermore, such pyrolysis machines from Beston Machinery currently have five to eight years of lifespan, so the return on investment is often not as great as advertised. However, as long as you find good deals on pyrolysis plant for sale online, you are sure to make some decent annual profits.

Moreover, we are glad to introduce Beston Machinery to you, which is a top-quality waste management machine manufacturer in China. Their products, including waste pyrolysis machine, charcoal making machine, waste sorting machine have been highly praised by customers around the world, such as the UK, the Philippines, Indonesia, etc. With rich experience and professional team, they always provide clients with a customized waste recycling business plan. If you are going to start a waste management program, contact Beston first.