Carbon Capture in the Crucible: Biochar’s Role in Metal Refining

In the ever-evolving landscape of industrial processes, the pursuit of sustainability has become a paramount goal. Among the industries that face environmental challenges, metal refining stands out due to its energy-intensive nature and significant carbon footprint. However, a promising solution is emerging in the form of biochar by biochar equipment, a carbon-rich material derived from biomass. This post delves into the innovative concept of using biochar in metal refining, exploring its role as a means of carbon capture in the crucible and its potential to reshape the environmental landscape of metal production.

I. The Carbon Conundrum in Metal Refining:

Metal refining, particularly in the production of steel and other alloys, traditionally relies on carbon-intensive processes such as coke-based smelting. The carbon used in these processes not only contributes to greenhouse gas emissions but also leads to the release of pollutants. As the world grapples with the consequences of climate change, finding sustainable alternatives to conventional carbon sources becomes imperative. This is where biochar steps in, offering a unique solution to the carbon conundrum in metal refining.

II. Understanding Biochar: Nature’s Carbon Sink:

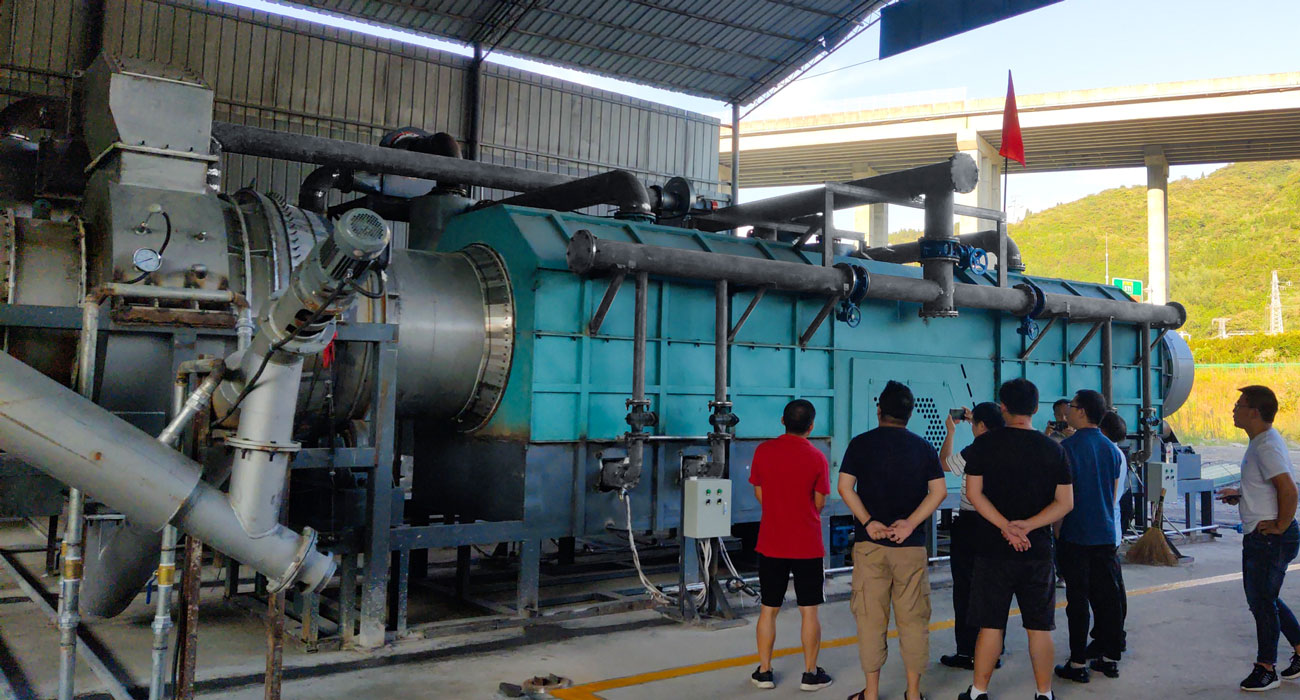

Biochar is a carbon-rich material produced by heating biomass in a low-oxygen environment, a process known as pyrolysis. The result is a stable form of carbon that not only sequesters carbon dioxide but also enhances soil fertility when used as a soil amendment. Harnessing the power of biochar in metal refining involves recognizing its potential as a sustainable alternative to traditional carbon sources. Use this small one as the start: https://bestonmachinery.com/biochar-production-equipment/mobile/.

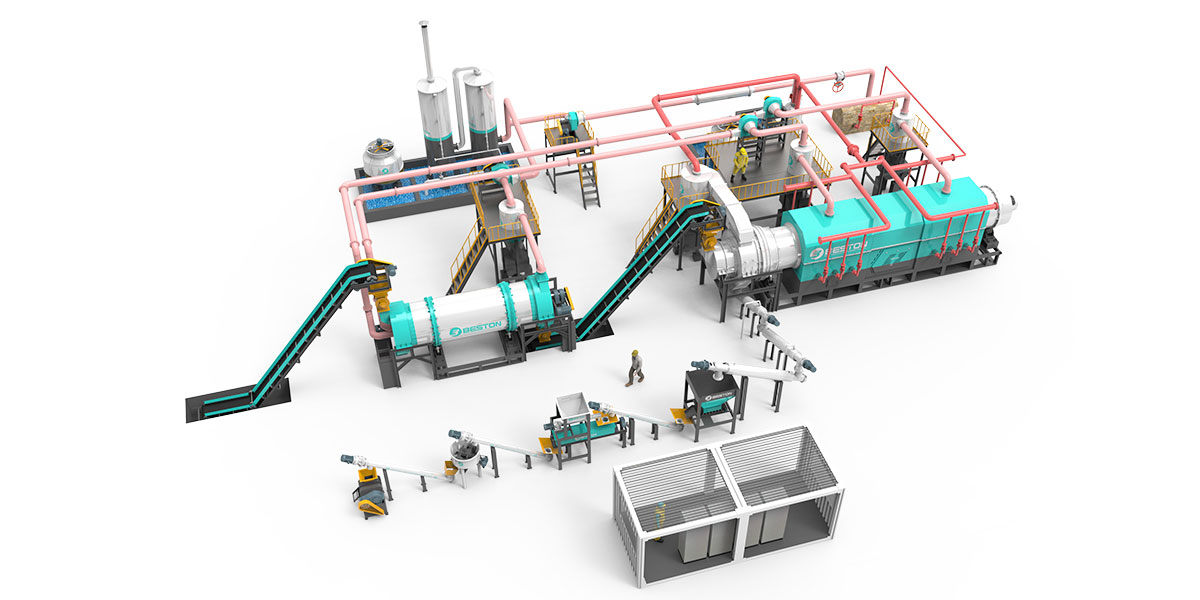

III. Biochar Production Methods for Metal Refining:

The production of biochar for use in metal refining involves specific methods tailored to the requirements of the industry. Different biomass feedstocks, such as wood chips, agricultural residues, or organic waste, can be used in the pyrolysis process. The choice of feedstock influences the properties of the biochar, including its carbon content, porosity, and reactivity. By optimizing biochar production methods, the metal industry can tailor this carbon-rich material to suit its specific needs.

IV. The Pyrolysis Process: Transforming Biomass into Biochar:

Pyrolysis, the cornerstone of biochar production, is a thermal decomposition process that occurs in the absence of oxygen. This prevents the complete combustion of biomass, leading to the formation of biochar. The process involves three stages: drying, pyrolysis, and cooling. The controlled conditions of pyrolysis allow for the capture of carbon from biomass without releasing it into the atmosphere. This carbon capture potential positions biochar as a sustainable alternative in the crucible of metal refining.

V. Biochar as a Reducing Agent: Transforming the Metal Refining Paradigm:

In traditional metal refining, carbon primarily serves as a reducing agent, facilitating the extraction of metals from their ores. Biochar, with its carbon-rich composition, can play a similar role, serving as a sustainable reducing agent in metal production. When introduced into the crucible, biochar reacts with metal oxides, releasing carbon monoxide and reducing the metal to its elemental form. This innovative application of biochar marks a paradigm shift in metal refining, aligning the industry with sustainability goals.

VI. Carbon Sequestration: Mitigating Greenhouse Gas Emissions:

One of the most compelling aspects of using biochar in metal refining is its potential for carbon sequestration. By capturing carbon from biomass and incorporating it into the metal production process, biochar acts as a carbon sink. This not only reduces the reliance on fossil fuels but also mitigates the release of carbon dioxide associated with traditional carbon sources. As industries seek ways to lower their carbon footprint, the carbon sequestration capability of biochar becomes a valuable asset in the crucible of change.

VII. Improving Energy Efficiency: The Biochar Advantage:

In addition to its role as a reducing agent, biochar contributes to the overall energy efficiency of metal refining processes. The combustion of traditional carbon sources, such as coke, releases large amounts of energy in the form of heat. Biochar, when used as a carbon source, provides a more controlled and efficient release of energy. This improved energy efficiency not only enhances the sustainability of metal production but also reduces the environmental impact associated with energy-intensive processes. When making charcoal, the biochar pyrolysis reactor is important.

VIII. Enhancing Metal Quality: The Biochar Influence:

The introduction of biochar into the crucible doesn’t just impact the environmental footprint; it also influences the quality of the produced metal. Biochar’s unique properties, including its porous structure and mineral content, can enhance the properties of the final metal product. In certain applications, biochar may contribute to improved hardness, strength, or other desirable characteristics. This dual functionality of biochar, as an environmental ally and a quality enhancer, underscores its potential in reshaping the metal refining landscape.

IX. Challenges and Considerations: Integrating Biochar into Metal Refining:

While the potential benefits of using biochar in metal refining are significant, several challenges and considerations must be addressed for successful integration. These include optimizing the composition of biochar, addressing variability in feedstocks, and developing standardized practices for incorporating biochar into existing refining processes. Additionally, ensuring that biochar production itself is carried out sustainably is essential to maintaining the environmental integrity of this approach.

X. Case Studies: Biochar in Action in Metal Refining:

Examining real-world applications provides valuable insights into the viability of biochar in metal refining. Case studies from pioneering industries and research initiatives showcase the successful integration of biochar into various metal production processes. These examples not only highlight the technical feasibility of using biochar but also demonstrate the positive environmental and economic outcomes achieved in the crucible of practical implementation.

XI. Economic Viability and Industry Adoption: The Path Forward:

For biochar to truly play a transformative role in metal refining, it must not only prove its technical feasibility but also demonstrate economic viability. Industry adoption relies on cost-effectiveness, scalability, and the ability to integrate biochar seamlessly into existing processes. As advancements continue and the economic case strengthens, the path forward for widespread adoption of biochar in metal refining becomes clearer. This website may offers more information for you: https://bestonmachinery.com/th/.

XII. Future Prospects: Biochar and the Sustainable Metallurgical Revolution:

Looking ahead, the future prospects of biochar in metal refining are promising. As research and development efforts continue, innovations in biochar production, refining processes, and integration techniques are likely to emerge. The sustainable metallurgical revolution, driven by the biochar paradigm, holds the potential to redefine the industry, ushering in an era of environmentally conscious metal production.

Conclusion: Biochar’s Crucial Role in Redefining Metal Refining:

In conclusion, the integration of biochar into metal refining represents a groundbreaking approach to address the environmental challenges posed by traditional carbon-intensive processes. Biochar’s role as a reducing agent, carbon sink, and quality enhancer positions it as a crucial player in the crucible of change for the metal industry. As the world strives for sustainability, biochar emerges as a promising ally, offering a path toward greener, more efficient, and economically viable metal refining processes. The journey from carbon capture in the crucible to sustainable metallurgy is underway, with biochar leading the way into a new era of environmental responsibility and innovation.