Enhancing Efficiency of Coconut Shell Charcoal Production

Coconut shell charcoal production is a valuable process that converts coconut shells, an abundant agricultural byproduct, into a high-value product used in various industries, including energy production, water filtration, and metallurgy. Improving the efficiency of this production process is essential for maximizing output, reducing costs, and ensuring environmental sustainability. Achieving higher efficiency involves optimizing various stages, from raw material preparation to the operation of the coconut shell charcoal making machine.

Raw Material Selection and Preparation

The efficiency of coconut shell charcoal production begins with the selection and preparation of raw materials. The quality of the coconut shells directly impacts how to make coconut shell charcoal. Ensuring that the shells are clean, free from contaminants, and properly sized can help improve the overall efficiency of the process.

1. Optimal Sizing of Coconut Shells

Coconut shells should be properly crushed or shredded into uniform sizes before being processed in the charcoal making machine. Consistent particle size ensures that the shells are evenly heated, leading to more efficient pyrolysis. If the shells are too large, the heating process may be uneven, reducing the overall yield of charcoal. Conversely, if the particles are too small, the process may lead to excessive dust and a higher likelihood of incomplete combustion.

2. Moisture Content Reduction

Excess moisture in the coconut shells can hinder the pyrolysis process, leading to energy loss and decreased charcoal yield. Drying the shells to an optimal moisture level, typically between 10% and 20%, before feeding them into the coconut shell charcoal making machine is essential. This can be achieved by air drying or using a dedicated drying unit, which ensures that the shells are adequately prepared for efficient processing.

Pyrolysis Process Optimization

The core of coconut shell charcoal making machine lies in the pyrolysis process, where organic material is thermally decomposed in the absence of oxygen. The temperature, residence time, and heating rate are crucial parameters that influence the efficiency of the process.

1. Temperature Control

The temperature at which pyrolysis occurs plays a significant role in determining the yield and quality of the charcoal. For coconut shell charcoal, the optimal pyrolysis temperature ranges from 400°C to 600°C. Operating the coconut shell charcoal making machine at the right temperature ensures complete carbonization, producing a high-carbon content charcoal with minimal volatile byproducts. Too high a temperature can lead to excessive gas production and energy loss, while too low a temperature results in incomplete carbonization and lower-quality charcoal.

2. Heating Rate Management

The heating rate, or the speed at which the temperature is increased during pyrolysis, also affects the efficiency of the process. A gradual heating rate is typically preferred, as it allows for more controlled decomposition of the coconut shells. Rapid heating can cause uneven carbonization and the formation of undesirable byproducts, while slow heating can increase the overall processing time. A balanced heating rate improves the efficiency and consistency of the production process.

3. Optimizing Residence Time

The residence time refers to the amount of time the coconut shells remain in the biomass pyrolysis plant. Longer residence times allow for more complete carbonization, but they also increase the energy consumption and the risk of over-processing. On the other hand, shorter residence times may result in under-carbonized material, reducing the charcoal yield. Fine-tuning the residence time based on the specific characteristics of the coconut shells and the desired charcoal properties can significantly improve efficiency.

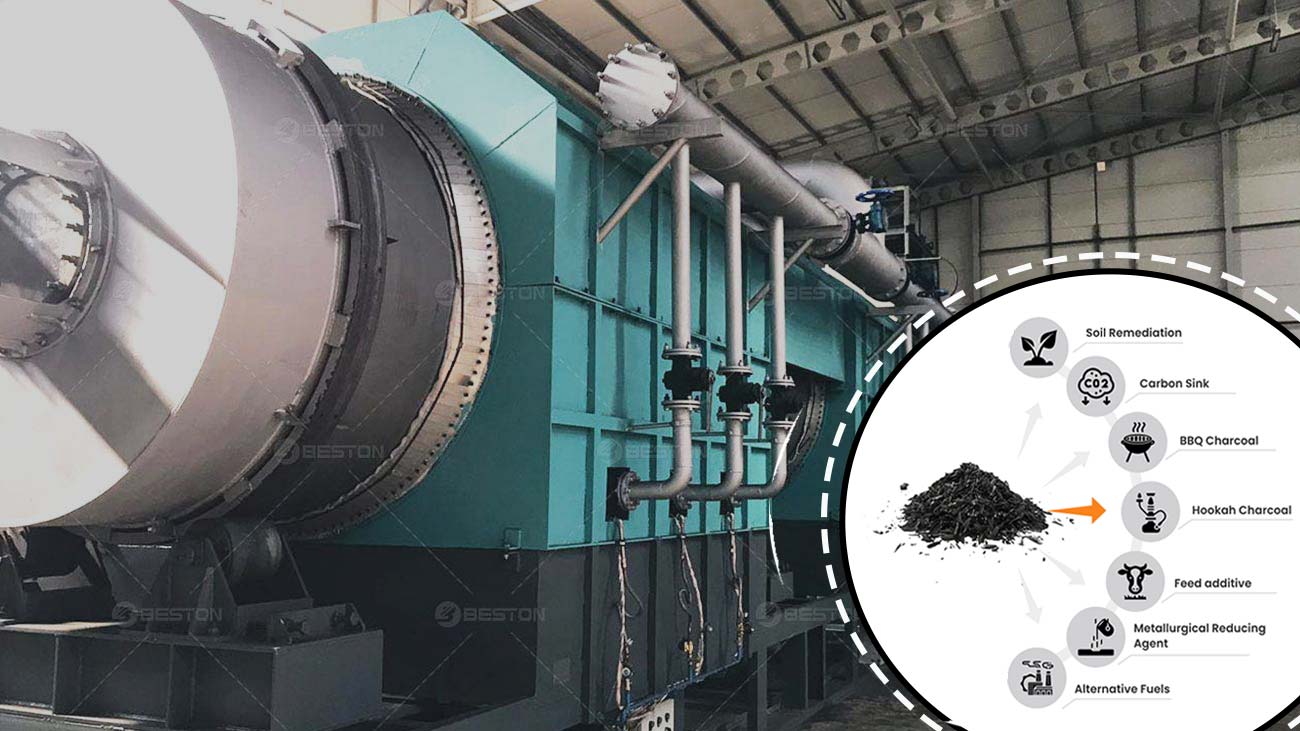

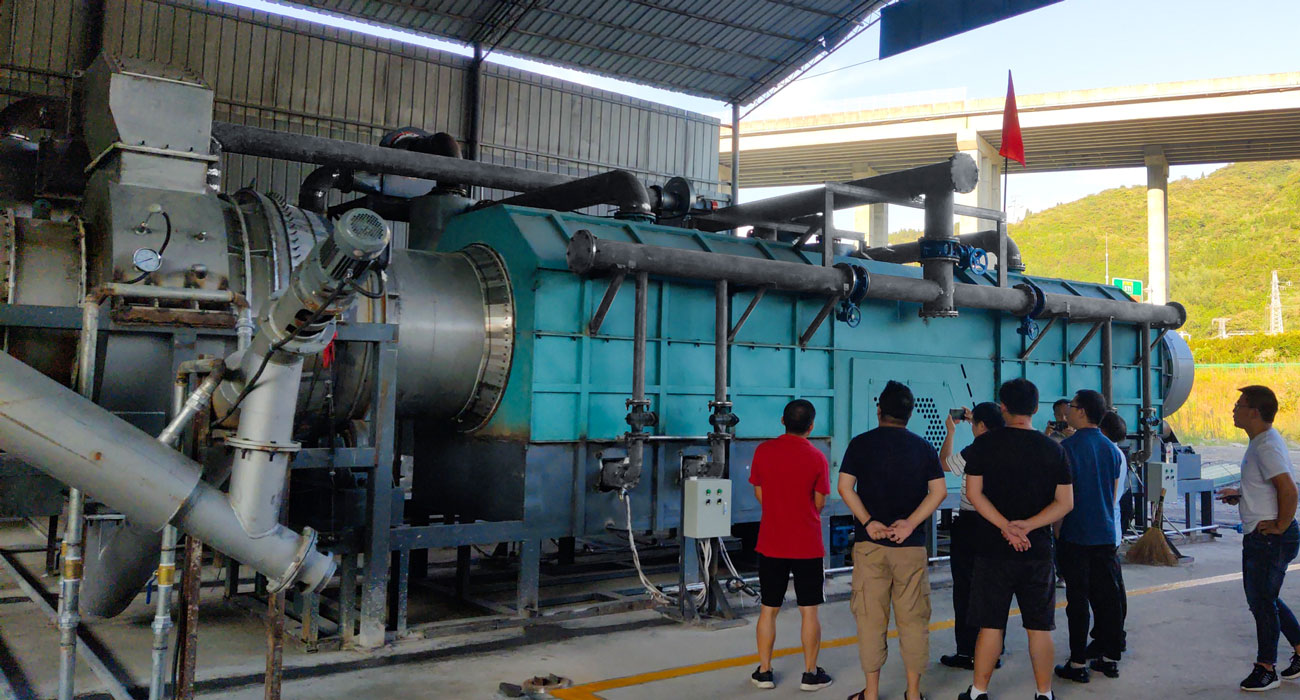

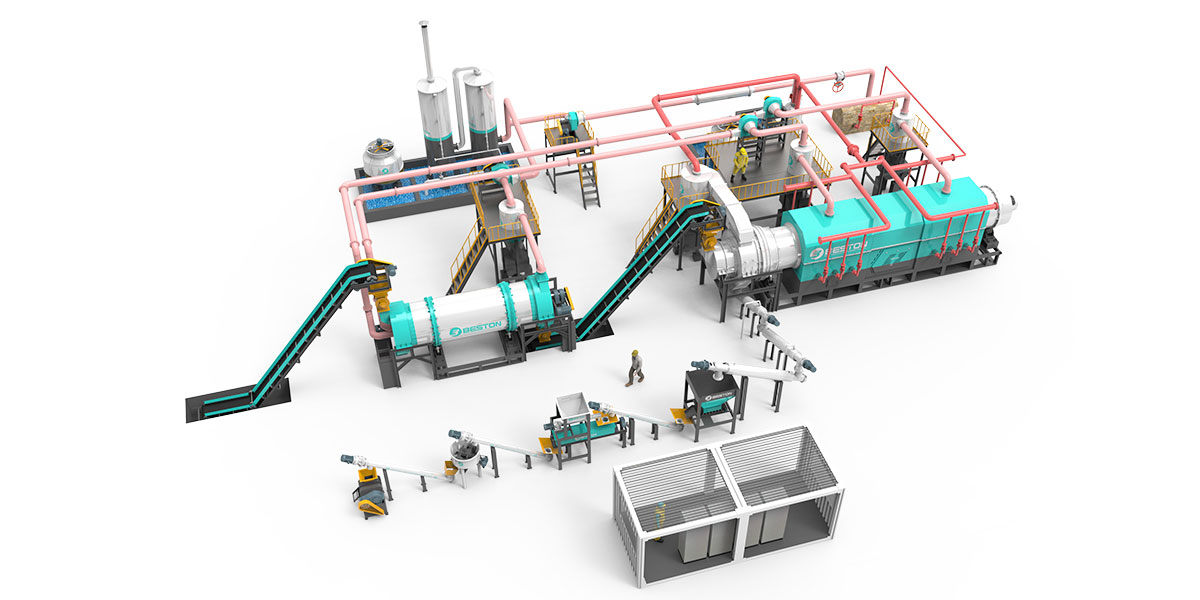

Technological Advancements in Equipment

Advancements in biomass charcoal machine technology can significantly improve the efficiency of the production process. Modern machines are equipped with features such as automatic temperature control, improved heat recovery systems, and enhanced gas collection mechanisms. These innovations help optimize the pyrolysis process, reduce energy consumption, and improve the overall yield of high-quality charcoal.

1. Energy Recovery Systems

Many modern coconut shell charcoal making machines are equipped with energy recovery systems that capture excess heat generated during pyrolysis. This heat can be used to preheat incoming coconut shells or to generate electricity, reducing the overall energy demand of the process and increasing efficiency.

2. Automation and Monitoring

Advanced automation systems enable precise control over the pyrolysis process. Real-time monitoring of temperature, pressure, and gas composition ensures that the machine operates within optimal parameters, reducing the risk of inefficiencies and improving the consistency of the final product.

Conclusion

Improving the efficiency of coconut shell charcoal production requires a holistic approach that encompasses raw material preparation, process optimization, byproduct utilization, and technological advancements. By focusing on these key areas, operators can maximize the output of high-quality charcoal, reduce energy consumption, and enhance the overall sustainability of the production process. With the right strategies in place, the production of coconut shell charcoal can become a more efficient and environmentally friendly process, benefiting both producers and the wider community.