Design Features Of The Continuous Pyrolysis Plant

The purpose of a continuous pyrolysis plant is to change black pollution into renewable and usable energy. Not only does this plant change tyre to usable oil, it also assists in pyrolyzing rubber and plastic waste. As a result of waste management concerns, most governments have taken massive strides to address waste tyres. This continuous pyrolysis reactor is an excellent option if you are thinking about processing or disposing of waste in big quantities.

Continuous pyrolysis plant is but a single kind of pyrolysis plant that you can get. With modern tech advancing, pyrolysis plants are also advancing. Therefore, selecting the plant which is most ideal for you and your business is integral to success. To know exactly what you are getting into and the output you can expect, it’s essential that you know about the design.

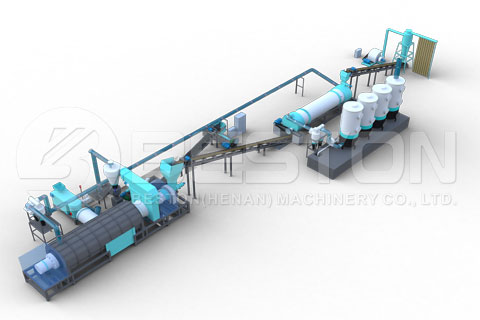

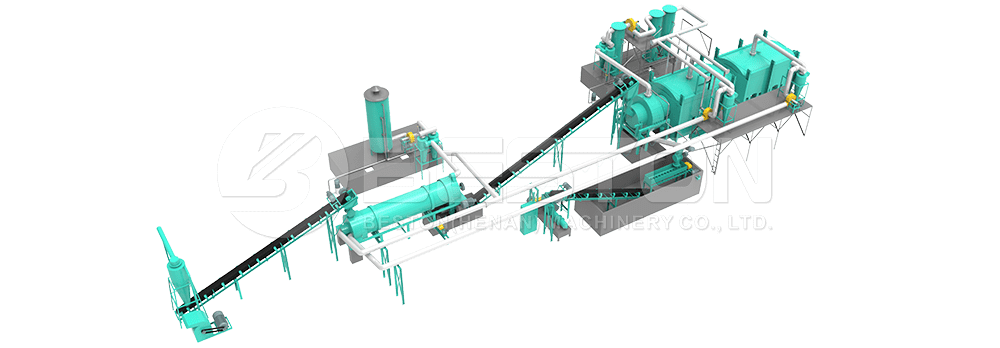

Continuous Pyrolysis Plant Design

The pyrolysis plant layout is unique. You should choose a service provider that continually betters pyrolysis tech and ultimate efficiency. Some of the unique design features include:

Quick & Continuous Feeding System

The screw conveyor continuously transports the waste tyre to the reactor. This equipment has these benefits.

It can decrease the oxygen to the extreme during the delivery procedure.

This section helps in minimizing the labor manual.

The feeding system isn’t blocked up easily.

Fast & Seamless Continuous Pyrolysis System

The reactor has two layers. The pyrolysis procedure begins upon reaching 180℃. The design of the double-layer makes the pyrolysis reaction more efficient. When operated properly, customers can expect this system to bring them an array of advantages.

The semi-continuous reactor essentially operates similarly to the batch reactor. The main distinction comes from the feeder. This seamless system incorporates automatic feeding equipment, which assists in speeding up the entire pyrolysis system. Please see more details here: https://bestonasia.com/waste-tyre-pyrolysis-plant/.

Low-temperature Continuous Discharging System

To safeguard the safety of people and save on time spent on management, the discharging system is stocked with an automatic discharging machine and gear, a water-cooling system, black carbon tan, and so forth. The water-cooling system reduces carbon black temperature and stops air from gaining access to the flue. The entire procedure is safer as a result of this system.

Reduce Smoke Pollution Maximally – Dedusting System

Over recent years, the European and Asian government has stringent caveats for local factories to attain as compared to the previous decades. The emission of flue gas must be compliant with the EU environmental protection standard. Prior to discharge, waste smoke will pass water spray, water washing, and ceramic ring adsorption. All the discharging and feeding are sealed to ensure that no dust and ashes are in the workshop. Beston products can solve these problems.

Other design features of the continuous pyrolysis plant include:

The heating structure saves the amount spent on fuels and loads of energy, improving the working efficiency.

Protective casing to prevent the operator from getting wounded from the extremely high temperatures.

Small furnace door to ascertain the entire pyrolysis procedure is stable.

The thermometer and pressure gauge enables the operator to observe the status of the reactor in real-time.

100% fireproof and explosion-proof.