Investigating The Coconut Shell Charcoal Making Machines Market

There are lots of big players in the coconut shell charcoal making machines manufacturing industry, with most manufacturers serving the global marketplace. You will find that some of the leading charcoal making equipment manufacturers have customers in dozens of different places, including South Africa, South Korean, Indonesia, India, Norway, Brazil and more. The benefits of the best coconut charcoal making machine is that they have expedited shipping, reliable performance, innovate design conception, high-grade components, and first-class production processes.

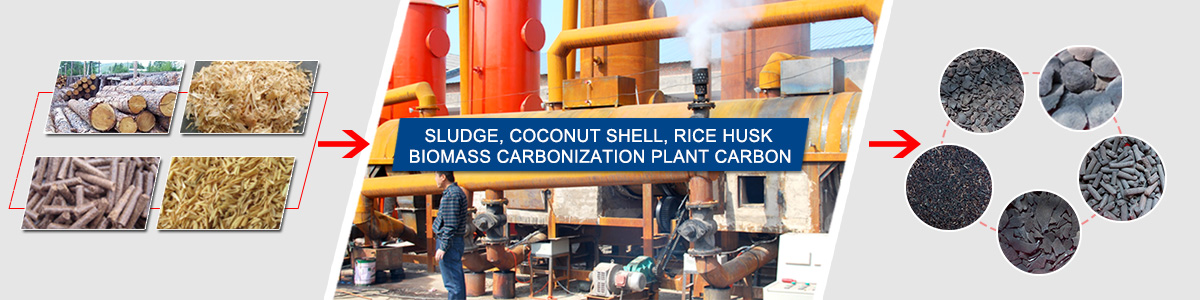

A coconut charcoal making machine employs super-high temperatures and oxygen-free carbonization technology to transform waste coconut shells into high carbon content charcoal and biogas. Both of those end products are in high demand, so it’s easy to generate a profit from their sale. The advantage of coconut charcoal is that burns cleanly and has high thermal energy capacity.

One of the most talked-about manufacturers of charcoal making machines is Beston. The company recently sold one of their showcase machine models to a processing plant in Holand. In addition to being able to convert coconut shells into charcoal and biogas, Beston’s biomass charcoal making machine can also process various other types of biomass materials including sewage sludge, agricultural waste, green waste, peanut shells, olive shells, sawdust, palm kernel shells, etc.

The continuous working operation of high-grade coconut charcoal making machines means they can run 24/7. This means that operators can generate large profits converting waste biomass materials into sought-after commodities. That said, machines with the highest levels of automation and continuous operation capabilities do require a substantial initial investment. One country that has recently started to embrace biowaste processing technology, like charcoal making machines, is Turkey.

Comparing Coconut Shell Charcoal Making Machines For Sale

When comparing different charcoal machines for sale online, there are parameters other than price that you need to take into consideration. While you obviously want to get the best value for money on your purchase, you also want to be sure you are buying a plant that has sufficient technical specifications for your processing facilities use case. There is no point purchasing coconut shell charcoal making machines with a maximum hourly feeding capacity of just 0.5 tons if you need to process hundreds of tons of waste coconut shells each week. Some of the specifications you need to check are hourly feeding capacity, reactor size, working method, reactor pattern, operating pressure, total power, cooling method, floor area, and expected service life. Most machines are compatible with a range of biomass-based raw materials, like palm kernels, bamboo wood, rice husks, and straw.