Avoid These 4 Mistakes When Buying A Charcoal Making Machine

There are thousands of manufacturers of charcoal making machines. These machines seem easy to make and anybody can copy a design. However, copying a design and matching the durability and reliability of the original components are two different things.

Many beginners in the industry often go to a vendor and buy whatever is recommended without doing their own research. More often than not, they have a bad experience as vendors always push machines that bring them the most money.

Here is what you need to know about common beginner mistakes to avoid when buying this machine:

1. Not Paying Attention to the Brand

Several buyers think that brands don’t really matter when it comes to machines used for making charcoal but they couldn’t be more wrong. It is true that you have to pay a premium for a brand name but that premium is worth the money. Brands care about their reputation and their customers.

They can’t afford to use poor quality components in their products. The charcoal making equipment has proper quality control processes in their manufacturing facilities. These processes ensure that every single piece of machinery that leaves their factory conforms to particular standards.

You can’t really expect a no-name brand to have some kind of quality control process. These no-name brands typically manufactured things in the back alleys and their only goal is to sell as much as possible without caring about their reputation or their customers.

2. Buying the Cheapest Machine

If you think that jute stick charcoal making machines perform the same and it doesn’t matter if you choose to buy the cheapest available option, you are in for a rude shock. Charcoal is made by burning off all materials other than carbon.

It requires extremely high temperatures and not every material is capable of withstanding those high temperatures for long. Surely, some materials will be able to withstand the high temperatures for a few weeks or months but the material will eventually start cracking and developing problems.

This is why it’s important to care about brand and quality of components used for making the machine.

3. Ease of Operation & Maintenance

Several types of charcoal machines are in use today. However, not all the machines are easy to operate or clean. Regular cleaning & maintenance is essential to keep the machine operating at optimum efficiency. If the machine isn’t cleaned regularly, it may consume more fuel or the quality of charcoal may not be as good as can be achieved with a completely clean machine.

If a machine isn’t easy to clean, the operator may not clean it completely or may clean it completely only once in a while and not after every batch. This is why you need to pay special attention to the ease of use and maintenance.

Consult your machine here: https://bestonasia.com/charcoal-kiln-for-sale/.

4. Buying the Recommended Machine without Doing Own Research

Most people will go to a vendor and ask them to recommend a model. They often don’t do their own research. What they don’t realize is that the vendors are inclined to recommend machines with the highest margins.

Those machines may not be bad but they are also not going to be the best available machines within your budget. This is why you need to do your own research and focus on the quality of components instead of price.

Conclusion

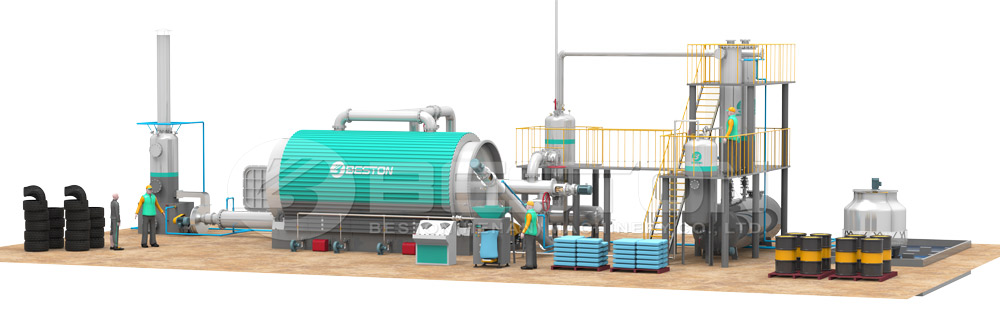

Overall, a charcoal making machine is a great investment. Charcoal is in high demand but only when it is of the highest quality. This is why you should pay special attention to the brand, quality of components, ease of use, and ease of maintenance to get the best value for your money. Beston Group Co., Ltd. will be a good choice.