Buy The Right Pulp Molding Machine to Enjoy Its Benefits

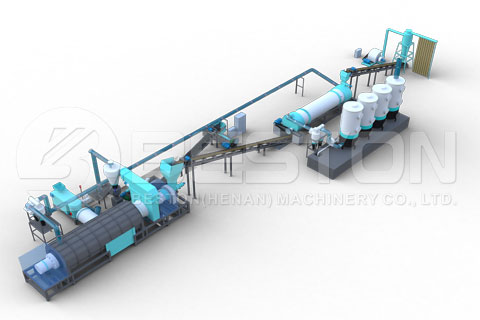

If you are looking to make paper tray products such as egg or fruit trays, you’re going to require pulp moulding machinery in order to make many cartons at a low cost. These machines can make thousand of trays relatively fast and at an affordable price. Also, the materials needed for production are easy to acquire.

One of the best things about investing in a pulp molding machine is that it’s good for the environment and uses recycled products meaning it does not put any strain on the system. You can get rid of huge amounts of recycled with this machinery and the fact that it is eco-friendly means it will not put any strain on the environment.

Another great thing is that paper pulp molding machines are available at reasonable prices. The cost depends on the size and the power of the machinery. The automatic type produces a lot of cartons compared to its manual counterpart, and so, you can expect the price to be relatively higher. However, as the size of the machinery goes down, so does the price. As such, if you are new to this industry, an automatic egg tray machine of Beston Company should be an excellent starting point.

An ideal machine can convert any form of paper waste into pulp. The pulp is then molded into any form of tray you need. If you have the automatic type, it will handle everything from forming the mold and drying it to stacking it. There are many things you can convert into egg trays, including cartons, waste paper, and old newspapers. The waste paper is mixed with water, where it’s converted into pulp. When the pulp is made, it is passed through a huge vat where it undergoes refining.

However, you need the right machinery in order to enjoy these benefits. This is where doing your homework comes in handy. There are numerous manufacturers and sellers out there and you need to be wary of the unscrupulous kind. The last thing you want is to spend your hard-earned money on a subpar product. The best manufacturers provide high-quality and long-lasting pulp molding machines. They also give warranties that last for years, thus providing a guarantee of optimal performance for a longer period.

Read reviews, testimonials and seek recommendations from people in the same industry when choosing a pulp molding machine. With these tips, you should be able to get egg crate making machine for sale that meets your needs.