The Usefulness Of The Oil Sludge Pyrolysis Plant

Oil sludge is produced from several processes within the oil and gas industry. These include but are not limited to drilling, refining oil resources, and even during the exploration phase. The sludge produce usually contains water, oil, and sludge that eventually becomes harmful to the environment. So read on as we discuss the oil sludge treatment plant.

After accumulating for a period of time, pollution begins to increase. This happens when these pollutants are not efficiently processed. However, oil sludge contains a significant amount of oil. Oil is among the most pressured resource globally and it can provide a potential income for those who are interested in processing it. The most professional tyre pyrolysis plant manufacturers in China are here.

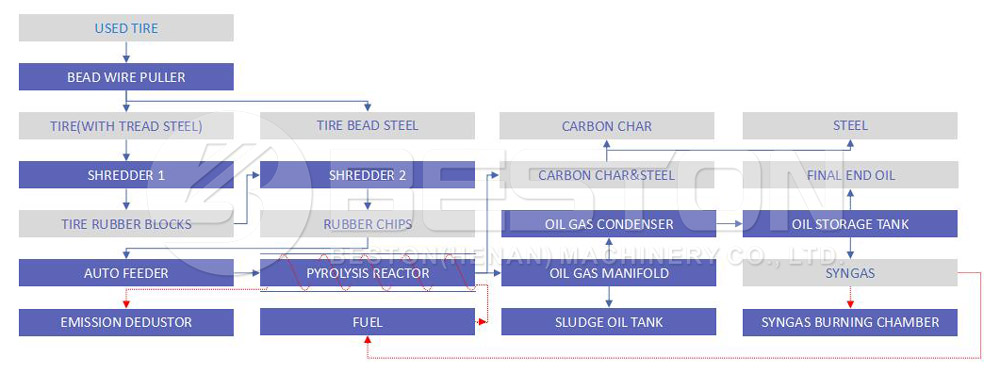

Processing can be done with the use of an oil sludge pyrolysis plant. While unprocessed oil creates many issues for the environment, there are several non-governmental organizations that take the initiative to create a better environment for future generations. When this happens, valuable fuel oil is produced and it is a great form of reducing the catastrophic environmental pollution that can happen.

Oil sludge plants usually come equipped with a feeding system that works automatically. This enables direct condensation methods to cool the gas. This then converts it to a liquid form. During the process, wastewater is produced along with exhaust gas.

However, it is also dedusted to further protect the environment. These plants also come with a reliable pressure gauge and a warning device that signals when things are in the process of becoming dangerous. When it comes to treating the waste oil sludge, these plants are very useful: https://kingtigergroup.com/oil-sludge-pyrolysis-plant/.

Finding a solution to oil sludge became quite a challenge. Since oil sludge is produced from oil field operations, water is also a factor. The plant ensures that water is separated from the sludge in order to render it useful once more. Pyrolysis plants are known for producing some of the best quality fuel oils around the globe.

Related product: https://kingtigergroup.com/used-oil-recycling-plant/.

The oil sludge pyrolysis plant was also created with a hydroseal that stops flames from burning while sulfur and other impurities are being burnt. This then creates a clean desulfurized version of gas. While all these things are taking place, there is still a huge risk of things going wrong. This is rectified with the use of safety tech.