Understanding the Costs Of Tyre Pyrolysis Plant and Many Benefits

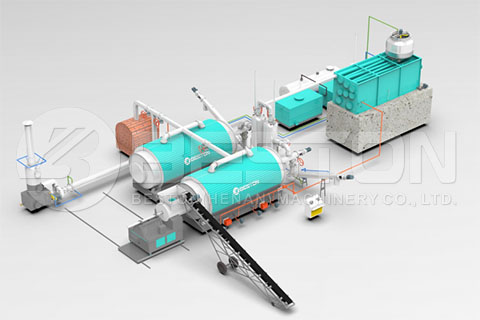

Have you been considering the purchase of a scrap tyre pyrolysis plant? You may be unsure if the cost is going to be overwhelming and if there is really any chance of profit with this type of business venture. The truth of the matter is that there is never truly a guarantee in any business. However, the odds of gaining a profit with a tyre pyrolysis plant are far greater than average. We are here to discuss the tyre recycling plant cost and choosing a location for one.

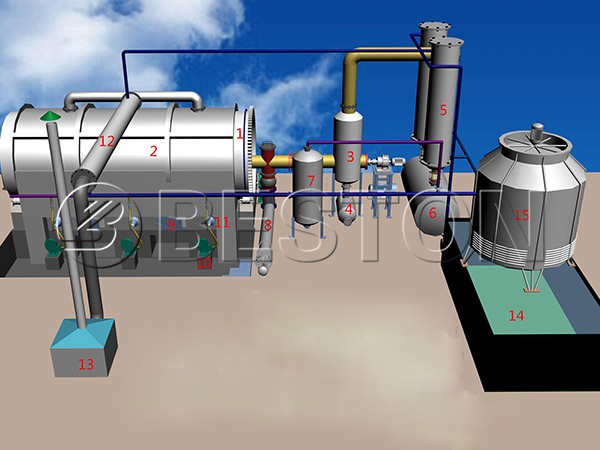

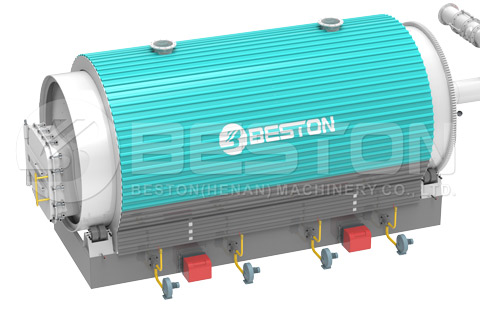

One of the first things one will need to consider with the cost of a tyre pyrolysis plant is choosing to build a new plant or purchasing an existing one. For many people, the thought of building a new plant can be rather overwhelming. However, it allows for you as a business owner to completely customize the plant to your specifications and desires. The downside to choosing your own build and model is the fact that it is going to be a rather expensive and complicated process. Check the related blog for more information: http://wasteenergymachine.webstarts.com/.

The other option is choosing an existing facility and altering it to your needs or using it as is. This is a much cheaper alternative and allows you to begin the operation and sales process much sooner. However, in many cases, there will need to be extensive updates and repairs done to the facility to make it efficient and compliant. While it is not possible to get the exact specifications in this scenario, quite a bit of money can be saved. In addition, it is much easier to get going and start producing a product at a much sooner scenario.

Once you are certain to the pyrolysis plant for sale you desire, you are going to need to find either the facility or the land to build it on. This can be much harder than it sounds. However, in this case, we are going to recommend speaking with a professional commercial real estate agent. They will be able to direct you to either the correct piece of property or a structure that may already be for sale. A real estate agent in this scenario can truly make the process effortless and allow you to work on other projects and situations you have in your business and life. If you do not find anything presently, they will continue to search the region for you.

Finally, there are websites devoted to the buying and selling of tyre pyrolysis plants around the world. While it may be difficult to find a plant in your specific area, you may be able to snag one that is close to your home base. These websites can be found by simply searching online for them. Here is a great website for your reference: https://beston.co.za/waste-tyre-pyrolysis-plant/.

As you can see, there is much to be concerned with other than the price of tire pyrolysis plant. One needs to identify the type of plant as well as an excellent location. However, if it all comes together, there is a large opportunity for profits.