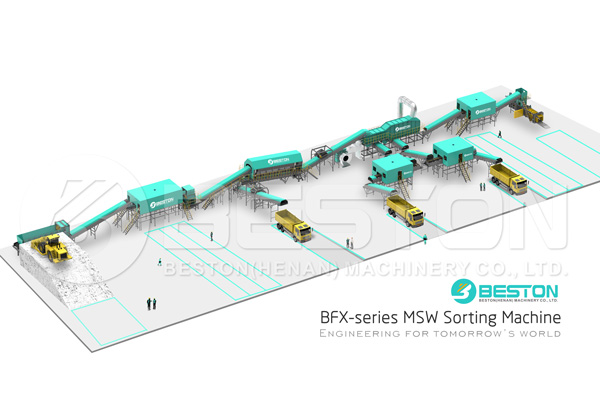

Features and Working Process of the Automatic Garbage Sorting System

Garbage sorting system is a machine used in recycling the urban garbage solid waste into organic matter, plastic, inorganic matter, unrecoverable gas, fuel and sand without environmental pollution. Garbage waste is harmful to the environment because it destroys the natural beauty of the environment, pollutes the environment and spread diseases. That’s why with the introduction of advanced technology, the garbage separation machine is available to reduce the growing number of urban garbage solid waste by recycling the waste to make useful and valuable resources for use.

A garbage sorting system is customized according to different requirements and raw materials so as to maximize the benefits of a customer.

Features of a Garbage Sorting Machine

1. Conducive to labor cost.

The garbage sorting system has an automatic system, therefore, the whole operation process needs a few people to operate.

2. The working model is fully sealed.

The waste sorting machine has a special odor control system that prevents bad smell from leaking out of the workshop. This protect the health of workers and also the surrounding environment.

3. Environmental friendly.

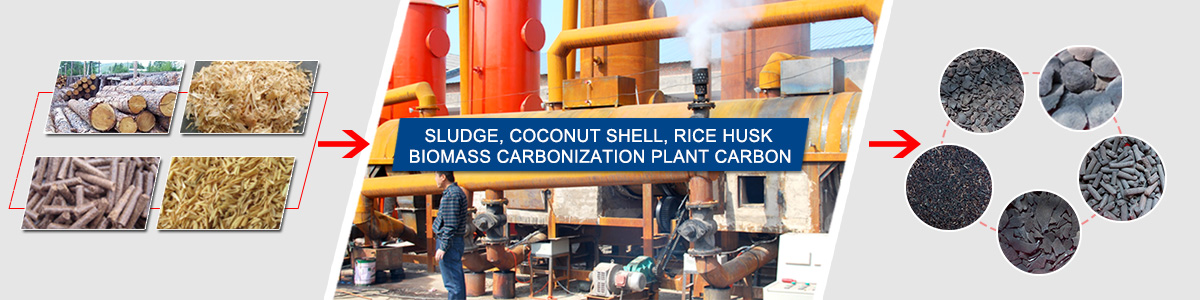

The unrecoverable combustible gas produced in the process is recycled for carbonization thus reducing environmental pollution. The garbage sorting system can therefore achieve the standard of environmental protection.

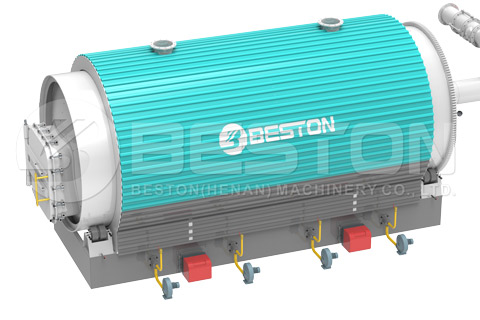

4. Equipment is advanced.

The garbage sorting system is invented by professional teams who have sufficient research knowledge, skills, and development experience to make a good quality garbage recycling plant. The system, therefore, has a low failure rate and the use effect is perfect.

5. Easy to operate.

The garbage sorting system has high automation which makes the production process easy and safe to handle. The operator will not have to spend a lot of time when operating the system.

6. Customer sales services.

Customers who are interested in buying a garbage sorting system are given both pre-sales and after-sales services. The pre-sales services include site visit before buying the system, training on to how to use the system. After sales services include: installation assistance by experienced engineers, professional team for consultation, quick wear supply, updates of the product.

The raw materials used in the garbage sorting system include municipal solid waste, household waste, industrial waste, landfill waste, and mining waste.

Garbage System Sorting Working Process

1. At first, the garbage waste in the truck is unloaded on the discharge area, then to the feeder system.

2. When the waste is distributed uniformly, it is then deposited to the manual sorting area. The workers’ sort and select large objects and hazardous waste.

3. After the manual sorting, the garbage is deposited to the screening machine where it is screened for treatment.

The machine then divide the garbage into two parts: large size of more than 50mm and small size of less than 50mm. The small size of less than 50mm is organic matter, and the iron objects in it is deposited for treatment in the compost workshop.

4. The iron objects of size more than 50mm is sorted out through magnet separation. The garbage that is larger than 50mm is taken to winnowing machine and wind election treatment takes place. The machine then sort out the garbage into three parts: Heavy materials, light plastic waste and secondary heavy materials.

5. Lastly, the three kinds of recycled waste are deposited to different areas that are equipped with automatic garbage segregator for further processing and for picking out useful substances before recycling: https://www.bestongroup.com/automatic-waste-segregation-machine/.

Application of garbage sorting machine end products

1. Inorganic materials can be used to produce bricks.

2. Organic materials can be used to produce fertilizer after hydrolysis.

3. Brick and stones can be used to improve the quality of the soil.

4. Plastic can be recycled to produce new plastic products.

5. Metal is used for recycling or it can be sold directly.

6. The unrecoverable combustible gas can be recycled to reduce waste pollution.

Garbage sorting system reduces garbage waste in our environment without air pollution during the production process. It brings environmental benefits, social benefits and improves the economy of the country.

The garbage sorting system is, therefore, a great opportunity for investment because the garbage waste must be reduced to avoid environmental pollution and in return, you get great benefits from the end products.

When planning to invest in the garbage sorting system do thorough research on which company to purchase the system from and the model that you desire. The company like China Beston Company should be offering good services that suit your needs.