Get A Qualified Waste Pyrolysis Plant For Sale

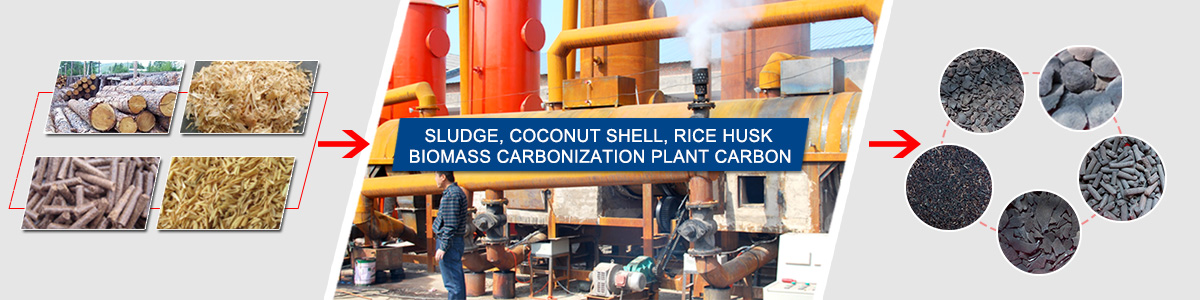

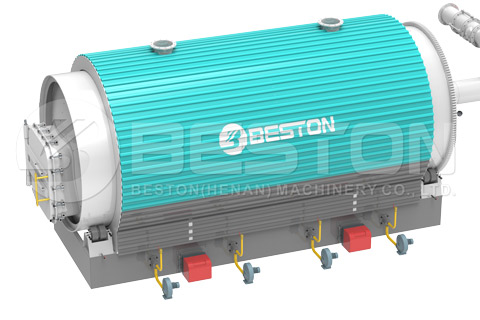

Waste pyrolysis plant for sale have been made for many decades. What is even more popular are the pyrolysis plants that can go through a substantial amount of material. This organic waste can be processed into charcoal and reusable fuels. Some people have created entire industries based upon doing nothing more than processing recyclable waste. The cost on these plants has come down in recent years, making this affordable for even small businesses to get into. If you have access to solid waste that can be used with these pyrolysis plants, you will need to find a pyrolysis plant for sale.

How Lucrative Can These Be If You Make This Type Of Investment?

You can make a sizable investment into one of these plants if you are getting one of the largest ones available. They are able to go through thousands of tons of material very easily. If you have a smaller business, you may want to consider getting a smaller plant to start off with. You can then expand your operations as you start to get access to more waste that you can use. If you are in charge of a municipal solid waste business, especially at a major city, it would be in your best interest to get the largest one available. Finding machine with different capacity on https://bestonmachinery.com/tyre-pyrolysis-plant/.

How To Get Good Deals On The Largest Pyrolysis Plants

As you look for a waste pyrolysis plant for sale, consider looking at the largest ones being sold. Larger businesses will always need the biggest models that are currently being manufactured. Try to work with a company that is well-known, if not the largest in the industry, but never discount smaller companies that may make something that is more affordable. Once you have made your investment, and it is running, you will see why so many people are getting into this industry. To imagine that you can take solid waste and change that into a marketable product, it’s hard to believe that more people are not doing this regularly. Recommend a trustworthy manufacturer for you: bestonmachinery.com.

Regardless of where you purchase these, you are always looking for a fantastic price point. A waste pyrolysis plant that is affordably priced is your primary goal. This may come from countries like South America, India, or China, and your research will help you make the right determination. The different components will be shipped for an affordable rate, and you can even purchase more than one assess how much solid waste you have access to the and then place your order. If you have done your research properly, you will soon have a very profitable side business processing solid waste.

If you need to find a waste pyrolysis plant today, start looking on the web. Companies are advertising at all times. It doesn’t matter if it takes a few weeks to arrive at your location. You will have purchased one of the best pyrolysis plants that can convert all of your applicable solid waste into marketable products that people will buy every day from you.