High Profitable High Quality Charcoal Manufacturing Machine Sale

Charcoal manufacturing machines are used in waste processing plants all around the world for the purposes of converting biomass waste into high-grade charcoal. A few examples of the types of waste that can be processed with a biochar furnace include palm kernel shells, sawdust, coconut shells, olive shells, wood, bamboo, straw, peanut shells and more. There are waste processing businesses from all parts of the globe investing in biochar production equipment including those located in Turkey, the United Kingdom, Syria, the Philippines, South Africa, Argentina, Brazil, Australia, etc.

Demand for charcoal manufacturing machine for sale is forecast to increase dramatically in the coming years are more regions seek to find eco-friendly and profitable ways to process mounting quantities of organic waste materials. Some of the lowest cost biochar machines for sale are manufactured by Chinese companies. The main reason that China has some of the best and cheapest machine suppliers is that labor costs and raw material costs are lower in Asia than in many other parts of the world.

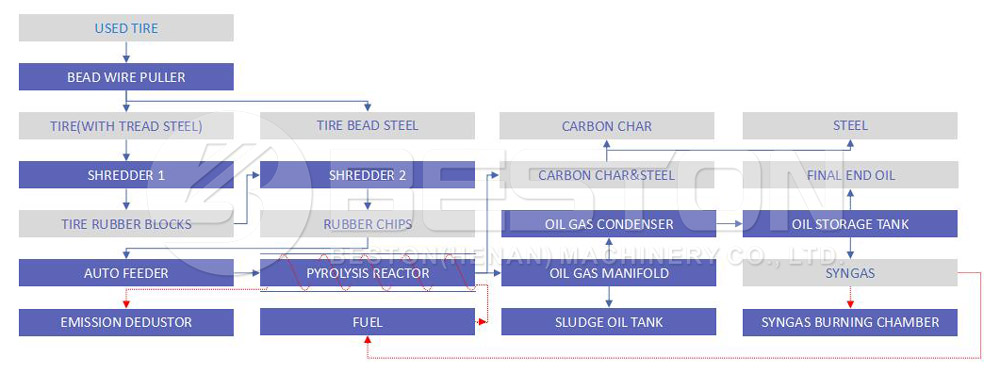

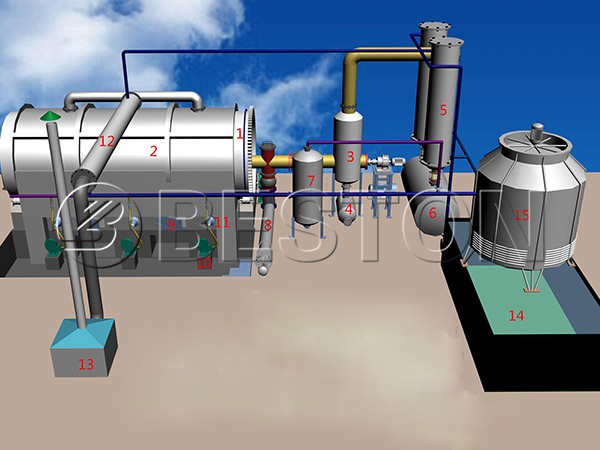

The final products that result from biomass carbonization include high carbon charcoal, wood vinegar, tar, and biogas. Both tar and wood vinegar can be sold to various chemical processing facilities. Biogas, meanwhile, can be used to refuel the carbonizing furnace. Alternatively, it can be stored in pressurized tanks and sold directly to industry. Since biomass charcoal has a very high carbon content (90%+), it has a high caloric value and excellent clean-burning characteristics. Since the fuel burns cleanly with limited smoke, it is an ideal fuel source for use in barbecue cooking.

The majority of bio charcoal produced in biomass pyrolysis plant is sold as solid, carbon-rich fuel, but it can also be used to formulate a high-quality soil fertilizer that is sought-after by the agriculture industry. The reason bio charcoal is a great soil additive is that it is rich in micronutrients needed for crop growth, including calcium, nitrogen, zinc, phosphorus, and manganese, and it also improves soil aeration/drainage properties.

In addition to the fuel and agriculture sectors, bio charcoal is also valuable to the pharmaceutical industry and paint industry, as it can be converted into activated carbon, which is a key ingredient needed in the formulation of many medications and paints.

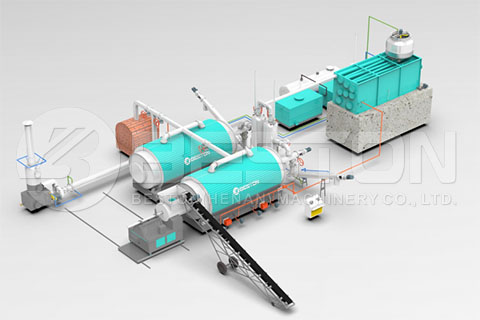

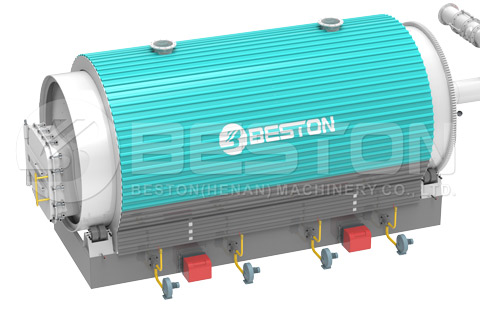

The good news about modern charcoal carbonization furnaces is that they can be fueled by a wide range of different sources, including diesel oil, LPG, natural gas, charcoal, biogas, coal, etc. In addition, there have excellent energy-efficient ratings, which means running costs can be kept to a minimum. Biomass waste processing businesses are able to make very healthy profits with modern biochar manufacturing machines. Investing in the right machine from day one is the key to making big profits in the biomass recycling industry. Find more information on Beston.