Why Most Businesses Choose To Use An Automatic Egg Tray Machine

Automation is really the key to expanding any business. The fewer workers that you need to use for your business endeavors, the higher the probability that you can expand your company rapidly. Automation has really changed the world in terms of the speed at which products are produced. This is certainly true when you are producing eggs that people use around the world. If you have a small local business that produces eggs, or if you are producing millions every year, and automated egg tray making machine is an investment that you need to make. Whether you have one of these, or several units working in tandem with each other, this is how you can locate the fully automatic egg tray machine.

Why Do Businesses Choose The Automated Versions?

The automated ones are chosen for three specific reasons. First, they allow you to employ fewer people. This can help you save in regard to your overall operating costs. Second, this will speed up the production of the many egg trays that you will need for your business. Third, you can save time in regard to setting everything up. Much of this will be done for you because of the way the machines are designed. In business, when you can save money and time, the final result is always going to be more revenue for your business. Click here to know more: https://eggtraymakingmachine.net/egg-tray-making-machine-price/.

How Do You Assess The Automated Egg Tray Machines That You Find?

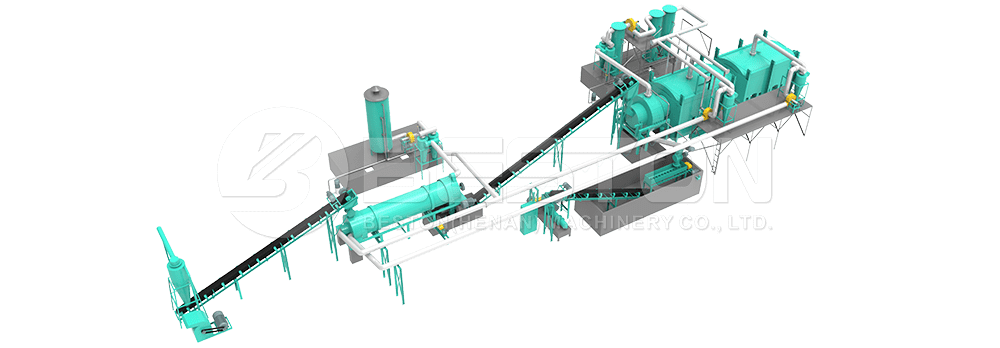

The automated machines that produce egg trays are numerous. These are perhaps the most popular that have ever been created. Each and every year, businesses that create these are making improvements. For example, if you purchased one a decade ago, the advancements that have been made are astounding. Your ability to produce 5000 or more egg trays per hour is a standard occurrence with the modern automated paper egg tray machines. The cost will be more than those that are semiautomatic, but the benefits that you receive are going to be well worth the extra cost that you are paying. To choose one, consider their size, capabilities, and how automated the entire process is. From the production of pulp, to the creation of the egg trays, everything needs to move smoothly.

You can find businesses that produce these every year online. Some of them have a decade or more of experience in producing egg tray making machines. The fully automated ones will be your main focus. You will compare different automatic egg tray making machines with other businesses. Eventually, one will look very appealing to you due to the way it is set up and perhaps reviews that you read. The company that you choose to work with should also provide a good guarantee on the functionality of that unit. Now that you have a better idea of why egg tray making machines that are fully automatic are useful, you may want to consider investing in one yourself. Whether your business is producing just a few thousand eggs per day, or several thousand per hour, the automated units are the best investment that you can make. More relevant information on the blog: https://bestoneggtraymachines.blogspot.com/.